Industrial Solutions

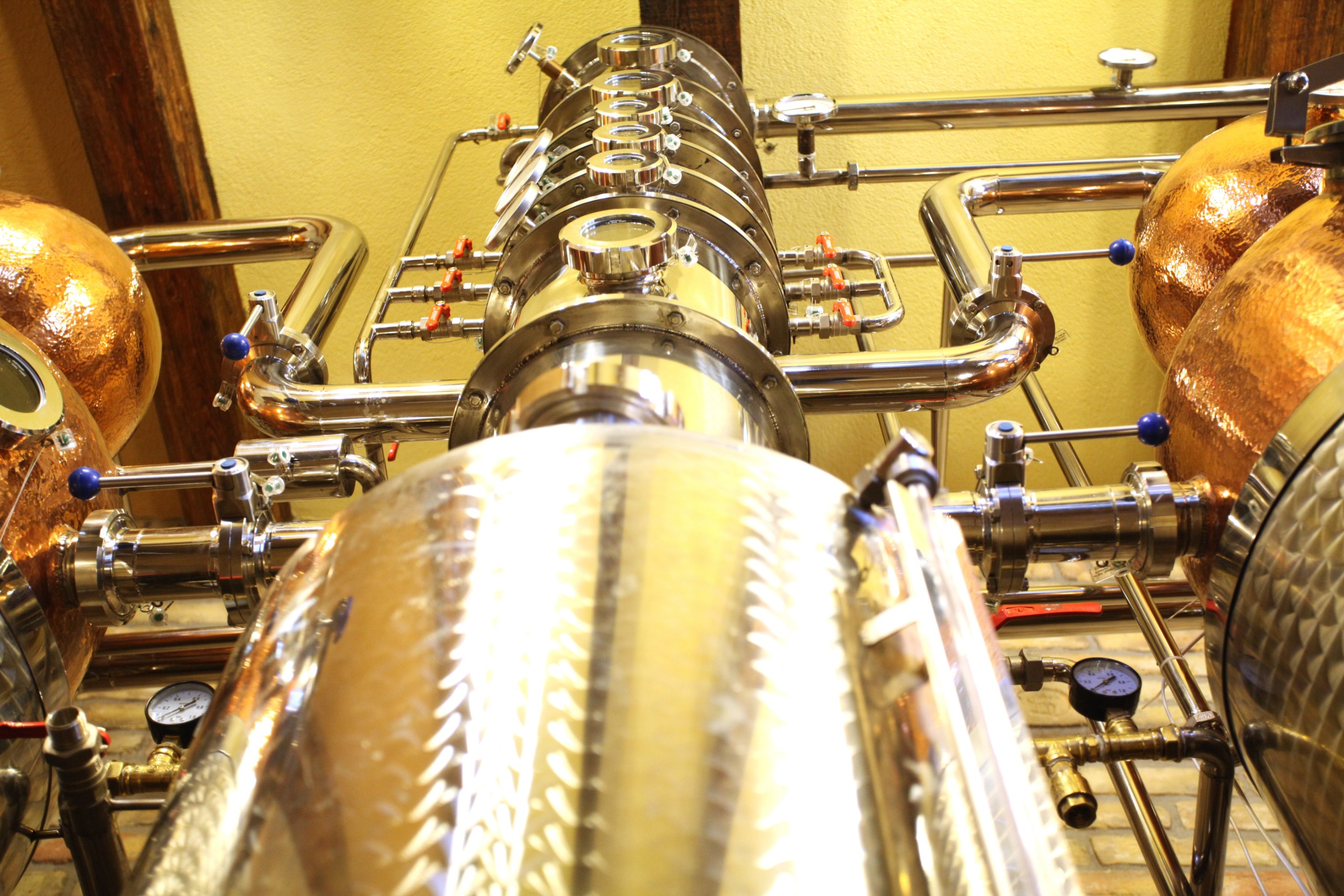

Alcohol System’s commercial and industrial distilleries are designed to produce any form of distillate or spirit you desire. Our locked system with a three-way tap allows for gin and spirit production under customs supervision in unlimited amounts.

Neutral alcohol distillation

Grain can be used to produce high-quality fine spirit or neutral alcohol (ENA). The technological steps of this process are:

1. Grain processing and hydrolysis (milling, dilution, heat treatment, enzymatic liquefaction and saccharification).

2. Fermentation.

3. Distillation (distillation, concentration, refining). If stocks of raw alcohol are available, only step 3 is sufficient.

We also undertake the design and construction of complete plants or the modernisation, renovation and conversion of old plants. If required, we can also supply beverage bottling equipment.

Bioethanol

Bioethanol is dehydrated alcohol, which may contain a maximum of 0.02% water. It is suitable as a blending agent for petrol and can be used as a less polluting propellant. If the dehydrated alcohol is to be produced by distillation, a completely different technique must be used. This is called Azeotropic Distillation. The raw material for distillation is usually concentrated alcohol (96 %). In the process, a third substance, benzene or cyclohexane, is added to the distillation column. This substance changes the boiling point conditions and thus allows complete separation of the water from the alcohol.

According to environmental trends, the demand for bioethanol is increasing. In the case of a surplus of products on the farm or at the farm and a low selling price, it is possible to produce raw alcohol from grain. In this case, the surplus can be easily stored for a long period as raw alcohol and sold on the market when the price of alcohol is right. The raw alcohol can be further processed either into fine potable alcohol or bio-ethanol (dehydrated alcohol).

Date:

03/22/2022